|

|

|||

| Go to page [Previous] 1~2~3~4~5~6~7~8 [Next] | ||||||||||

|

Michael Baker Eternal Order Near a river in the Midwest 11172 Posts

|

Quote:

On 2013-11-18 23:46, MikeHolbrook wrote: Interesting to hear this. I also have the Craftsman rotary tool (I like them better than Dremel). Here's the sick part... the last one I bought, I had to get at K-Mart... Sears only carried Dremel. WTF??? I use mine constantly. I have also gone through a handful of them over the years. I had gone the route of replacement parts, servicing, etc. Not any more. I chuck 'em and buy a new one. Far less aggravation and far less down time. Not saying your tip isn't useful, because it is sure to save someone's tool from the trash can. Thanks!

~michael baker

The Magic Company |

|||||||||

|

George Ledo Magic Café Columnist SF Bay Area 3044 Posts

|

This one is probably so obvious it's funny, but playing cards are fantastic for use as shims. They are very thin and hold up well.

For instance, when I made the Okito-Berg tipover chests for Joe Stevens, I wanted to make sure the inserts were perfectly centered in the outer boxes before I intalled the hinge. So I lined up the insert, then put an equal number of cards on each side between the insert and the box. Because the boxes were hand-made, there were very minor variations in size, but all I had to do was remove a card here and add it there until everything was balanced. The number of cards didn't make any difference as long as it was the same on each side. Now I'm making another prop for Joe, wich involves blocks inside a box. So I lined up the blocks on a wood blank, put a few cards at the end to allow for clearance, and there was my inside dimension. No measuring, and it was totally re-settable. I've also used them along the rip saw fence and on the cross-cut sled to add a bit of length to a cut. And I'm still finding uses for them. Of course, the cards go back inside the box after use, just like any other precision tool. When they get bent or damaged and can't be used as shims, they make great glue spreaders. And, in a pinch, they make good inside try squares. Who woulda thunk?

That's our departed buddy Burt, aka The Great Burtini, doing his famous Cups and Mice routine

www.georgefledo.net Latest column: "Sorry about the photos in my posts here" |

|||||||||

|

Michael Baker Eternal Order Near a river in the Midwest 11172 Posts

|

Great tip, George! Thanks! I have found many uses for playing cards, too. In addition to glue spreaders, they also work well to clean up squeeze-out from inside corners. Folded, they hold a nice crisp corner that works well... similar to the drinking straw idea mentioned here previously.

I will sometimes use playing cards as spacers when installing hinges on doors, etc. Just a bit of clearance between the two parts being joined usually insures that the parts don't bind, even if the screw snugs the parts a little too close together. It's better than trying to adjust the screws, and far better than springing the hinge a bit to get a door to close correctly.

~michael baker

The Magic Company |

|||||||||

|

George Ledo Magic Café Columnist SF Bay Area 3044 Posts

|

And one of these days I'm going to realize that, while glue is drying or I need a quick break, I can use them to practice the ol' front-and-back palm. A very versatile tool indeed!

That's our departed buddy Burt, aka The Great Burtini, doing his famous Cups and Mice routine

www.georgefledo.net Latest column: "Sorry about the photos in my posts here" |

|||||||||

|

Michael Baker Eternal Order Near a river in the Midwest 11172 Posts

|

Stop work pieces from sliding around on your bench. Buy a roll of mesh shelf liner, such as sold at Wal Mart. Cut a suitable section and lay it on the bench as your work surface. This good when you are using a palm sander on harder to secure pieces. It will prevent them from slipping around. When it gets too dusty to grip well, it is easy to wash... too old, chunk it and cut a new piece. You'll find this stuff comes in handy in a number of ways.

~michael baker

The Magic Company |

|||||||||

|

blamobox New user A shed in Somerset England 52 Posts

|

Quote:

On Feb 13, 2014, Michael Baker wrote: Good one! I have a roll of rubber carpet underlay I can roll out on the work surface. Double backed carpet tape is also handy for 'hard to clamp' material.

Time Ticks Away Like a Peanut............

|

|||||||||

|

gimpy2 Special user 960 Posts

|

I have found that those hotel door keys like a credit card are great little tools in the shop. They come in all different thicknesses that can be used for different needs. The thin ones are great for spreading glue I love the thick ones to put decals on with. to many uses to list them all.

Gimpy

www.gimpysmagic.com |

|||||||||

|

Michael Baker Eternal Order Near a river in the Midwest 11172 Posts

|

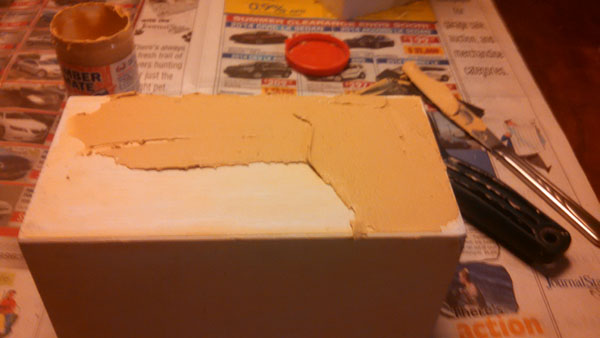

Some time ago, I mentioned a great product called Timber Mate water-based wood filler. I find it at a local Rockler store, but it is also available at Woodcraft, and probably some other places, too.

I am in the process of a refinish project and after stripping and sanding to the bare wood, noticed that the wood is heavily grained with lots of deep pores. These needed to be filled in order to give a good substrate for the primer and paint. Timber mate comes in a variety of wood tones, but for a painted project, it hardly matters what color you select. As it comes from the container, it is about the consistency of most other wood fillers, something like thick peanut butter. I have found that I get the best results by thinning the product somewhat with water, so that it spreads much easier without "pulling" up. The first photo shows the beginning process of spreading the filler over the wood. You don't need to be concerned with using too much. It actually helps insure that all voids are filled, and you cannot waste the product. Just spread it on like you are frosting a cake. I use a non-serrated butter knife for this. Don't worry... your wife won't kill you because this stuff is very easy to clean up.  The next photo shows the surface completely covered.  Finally, the excess has been drawn off using a wide blade putty knife. Mine is 4" wide. In order to do this, draw across the grain, not with the grain. In my project, the grain runs the length of the piece (left to right in the photos). When I scraped, I drew the blade from top to bottom, as the photo would show. If you draw with the grain, it tends to pull the filler out of the long channels of the grain. Drawing across the grain does not do this. Be sure to scrape off the excess from the blade after each pull. Just scrape it back into the container.  When the filler has dried completely (this won't take too long, but will depend on the depth of the fill), sand with a fine grade paper. I use 400 or 600 grit. Don't use a too heavy a grit as this can easily dig the filler back out. Prime and paint as usual. It shouldn't be necessary to mention this, but be sure to use paint and primer that is NOT water-based. Water-based products will dissolve the filler and it will wash right out. Enamel, lacquer, oil, etc. OK. Clean up is a snap, and even if the product has dried completely or gotten too thick over time, just reconstitute it with a little water and it's good as new again.

~michael baker

The Magic Company |

|||||||||

|

MentalistCreationLab Inner circle 1528 Posts

|

Michael,

I have a couple of questions about the Timber Mate. About how many of the props shown above would you say you could cover from a single can of the Timber Mate like the one your showing on the table? After the prop is covered how well does the paint stick in the terms of coats and blemishes. What I would like to know is does the paint merly rest on the top layer of the surface or does it soak in to the Timber Mate? Also when appling paint to the Timber Mate have you had any issues with blemishes do to the Timber Mate as some wood fillers seem to cause more problems when painting than they are worth, while they did fill the gaps and big hole it seems some of these fillers cause the paint to absorb in a rather unusual way. |

|||||||||

|

Michael Baker Eternal Order Near a river in the Midwest 11172 Posts

|

Hi Bill,

I could not really estimate how many items the product would cover because it would depend on the size of the object and the depth of the voids to be filled. The container itself is 2" diameter X 3" height, if that helps. 8 oz (250 gram) container. If you paint directly on this, there is going to be a bit of absorption. You'll notice the patched area to be less glossy than surrounding areas. You can fix this with multiple coats, but... I prefer to correct the substrate and properly prep it for paint first. Using a primer is a must, but I do that with all painted items anyway. I typically apply more than one coat of primer to any project, and with this, you can tell when the patch has been sufficiently blocked and color coats can be applied. (It's not that bad anyway.) Sanding sealer is also a must do, if you really want to get a primo paint finish. If you patch, then use sanding sealer before primer, you won't have any soak-in to speak of. BTW - the best sanding sealer I have found is Ace brand oil-based. Much better than water-based and fumes are not nearly as noxious as lacquer-based. If the stores don't have it in stock, they will order it.

~michael baker

The Magic Company |

|||||||||

|

MentalistCreationLab Inner circle 1528 Posts

|

Thanks Michael, that's what I wanted to know. I working on a project right now that may need a skim coat timder mate before painting as the woods grain is a bit more open than normal.

|

|||||||||

|

DaleTrueman Veteran user Australia 317 Posts

|

Quote:

On Dec 2, 2012, blamobox wrote: That is so awesome. You don't know how much this will help me! Thank you. |

|||||||||

|

jay leslie V.I.P. Southern California 9500 Posts

|

Tip for the day from a personal experiance not ten minutes ago....

It is unwise to get superglue on your tongue. Don't ask.

Jay Leslie

www.TheHouseOfEnchantment.com |

|||||||||

|

Michael Baker Eternal Order Near a river in the Midwest 11172 Posts

|

Quote:

On Apr 23, 2015, jay leslie wrote: I'm speechless... and I'm not the one with super glue on my tongue.

~michael baker

The Magic Company |

|||||||||

|

jay leslie V.I.P. Southern California 9500 Posts

|

So you think you're frugal? This will save you money if you have flying insects and dirty windows:

Wait till dusk, turn off your lights so the bugs migrate onto the window glass... get real close and spray the bugs... then wipe the glass clean with a paper towel. No sense wasting money on bug spray & glass cleaner when they do double duty.

Jay Leslie

www.TheHouseOfEnchantment.com |

|||||||||

|

JCorry New user 4 Posts

|

Although I am new to the forum I have some tips that I hope will help.

The first one is for super glue- the gloves that they use at places like Subway restaurant to pick up the sandwich ingredients will not stick to super glue as oposed to every thing else

This makes it much easier to for example hold an item together while glueing it. The second tip I'll share is to store your realy runny super glue in a pipette- it does not dry out and you can put as much as you want where you want it. Thanks to all who make this thread and the forum awesome! Jackson. |

|||||||||

|

Michael Baker Eternal Order Near a river in the Midwest 11172 Posts

|

Thanks, Jackson! Good tips!

~michael baker

The Magic Company |

|||||||||

|

Michael Baker Eternal Order Near a river in the Midwest 11172 Posts

|

Here's a solution to a problem...

I wanted to drill a hole through a ball. The problem was that the ball was only 1 1/4" diameter and I needed a 3/4" diameter hole. Obviously, you can't hold the ball while doing this, and conventional clamps and vices would scar the wood. So, I created a ball-drilling jig. I drilled a 1 1/4" hole through a piece of wood. The ball fit perfectly into this. Then I cut that piece of wood in half, the kerf running right through the center of the hole. The resulting gap allowed this to now be clamped in a standard drill press vice, securing the ball completely, without any damage to the ball. Having the jig completely surround the ball likely also prevented the sides of the ball from blowing out during the drilling process. This would work for any size ball, although you'd want the thickness of the stock for the jig to exceed the radius of the ball, so it clamps at the equator.

~michael baker

The Magic Company |

|||||||||

|

gimpy2 Special user 960 Posts

|

I often need plywood in very precise thickness. I don't have a drum sander and don't like running plywood thru one to start with. Found baltic birch came in thickness of down to 1/64" also bought 1/32" and 1/16". By gluing pieces on one or both of the sides of say 1/8" plywood you can make up any thickness you want and have a good paintable surface on both sides. I use contact cement to bond the layers.

Gimpy

www.gimpysmagic.com |

|||||||||

|

Michael Baker Eternal Order Near a river in the Midwest 11172 Posts

|

Good tip, Gimpy. I have also used that really thin stuff to "skin" a piece that may have surface issues. It's like adding veneer. Even though that thin Baltic Birch can be pretty expensive, sometimes it's better than rebuilding a project.

In a related topic to the thickness issue... I saw a tip on The Woodsmith Shop recently regarding the thicknesses of plywood. Sometimes the actual thicknesses are not accurate. So, if cutting a dado that the plywood must fit, and assuming the plywood is too thick, rather than resetting the dado blade or rip fence, use masking tape on the rip fence as a shim. Keep adding tape if needed to sneak up on the cut for a perfect fit.

~michael baker

The Magic Company |

|||||||||